Industrial fans play a crucial role in the waste recycling industry by improving air quality, optimizing material processing, and ensuring worker safety. From ventilation and dust control to drying and odor management, industrial fans are essential in recycling facilities to maintain efficiency and environmental compliance. Below is a detailed breakdown of how industrial fans are used in various waste recycling applications.

1. Air Filtration and Ventilation in Recycling Facilities

Recycling plants handle large volumes of waste materials, producing dust, fumes, and airborne contaminants. Industrial fans help maintain clean air quality by facilitating ventilation and air filtration.

-

Exhaust Fans: Remove airborne dust, fumes, and odors generated during material sorting and processing.

-

Supply Fans: Bring fresh air into enclosed areas to ensure worker safety and comfort.

-

HVLS (High-Volume, Low-Speed) Fans: Improve air circulation in large recycling warehouses to prevent heat buildup.

2. Dust Control in Material Sorting and Shredding

Recycling processes like shredding, crushing, and sorting create a significant amount of dust that can pose respiratory hazards and affect machinery performance. Industrial fans are integrated into dust collection systems to minimize airborne particles.

- Baghouse Fans: Capture and filter out fine particulates from shredding and grinding operations.

-

Local Exhaust Ventilation (LEV) Systems: Extract dust at the source, preventing it from spreading across the facility.

3. Fume and Odor Control in Organic Waste Recycling

Composting and organic waste processing generate strong odors and harmful gases such as methane, ammonia, and hydrogen sulfide. Industrial fans help in fume extraction and odor neutralization.

-

Activated Carbon Filtration Fans: Remove VOCs (volatile organic compounds) and foul odors from the air.

-

Biofilter Fans: Push contaminated air through biofilters that use microorganisms to break down odor-causing compounds.

-

Exhaust Fans in Composting Facilities: Control airflow to prevent odor accumulation in waste treatment plants.

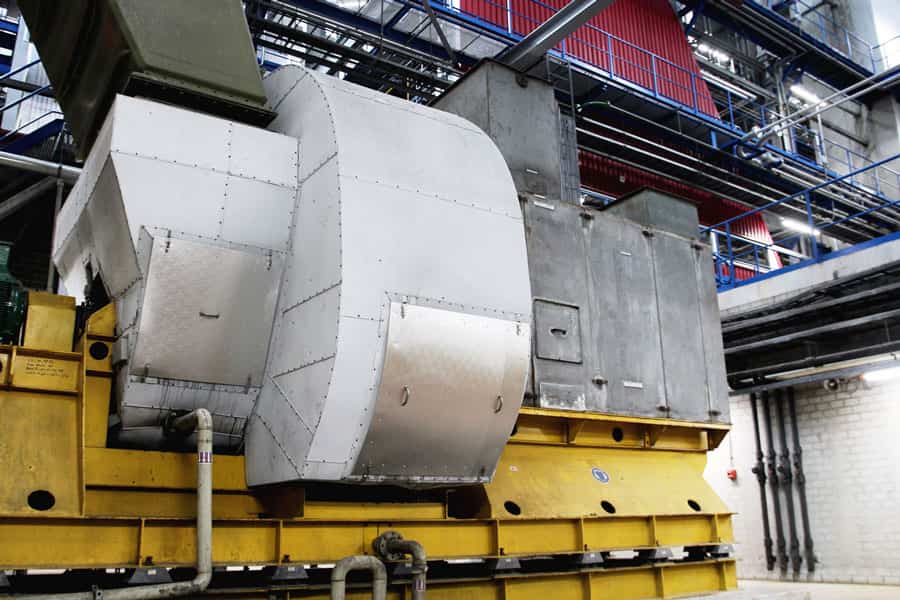

4. Cooling Systems for Machinery and Equipment

Recycling machines such as shredders, compactors, and conveyor belts generate heat during operation. Proper cooling is essential to prevent overheating and equipment failure.

-

Axial Cooling Fans: Used in machinery cooling systems to dissipate heat efficiently.

-

Centrifugal Fans: Provide airflow in cooling tunnels to maintain optimal operating temperatures.

-

Forced Ventilation Fans: Help regulate temperature in control rooms and electrical enclosures.

5. Pneumatic Conveying of Recyclable Materials

Industrial fans play a key role in pneumatic conveying systems, which transport lightweight recyclable materials such as paper, plastic, and metal shavings through pipelines.

-

Vacuum Fans: Create suction to move materials efficiently through air ducts.

-

Positive Pressure Fans: Push recyclables through conveyor tubes for efficient transportation.

-

Air Separator Fans: Help separate light materials from heavy ones in automated sorting systems.

6. Drying and Dehumidification in Recycling Processes

Many recycling applications, such as paper and plastic recycling, require materials to be dried before processing. Industrial fans assist in moisture removal, ensuring quality output.

-

Forced-Air Drying Fans: Accelerate drying times for wet waste, reducing processing delays.

-

Dehumidification Fans: Maintain low humidity in storage areas to prevent mold growth on recycled paper and textiles.

7. Fire and Smoke Ventilation for Safety Compliance

Recycling plants handle flammable materials such as paper, plastic, and industrial waste, increasing the risk of fires. Industrial fans are essential for smoke control and fire suppression.

-

Smoke Extraction Fans: Rapidly remove smoke in case of fire, improving visibility for emergency response teams.

-

Pressurization Fans: Maintain positive pressure in escape routes, preventing smoke infiltration.

-

Explosion-Proof Fans: Designed for hazardous waste recycling plants dealing with combustible dust and gases.

8. Waste Incineration and Flue Gas Treatment

In facilities where non-recyclable waste is incinerated, industrial fans are used to manage combustion air supply and flue gas treatment.

-

Induced Draft (ID) Fans: Extract hot gases from incinerators and direct them to pollution control systems.

-

Forced Draft (FD) Fans: Supply oxygen for efficient combustion in waste-to-energy plants.

-

Electrostatic Precipitator (ESP) Fans: Capture fine ash particles from incineration exhaust gases before releasing them into the atmosphere.

9. Hazardous Waste Ventilation and Gas Extraction

Recycling facilities handling hazardous waste, such as batteries, chemicals, and electronic waste (e-waste), require special ventilation systems to remove toxic fumes and gases.

-

Chemical Fume Extractor Fans: Capture vapors from chemical waste recycling processes.

-

HEPA Filtration Fans: Filter out airborne contaminants from hazardous waste handling areas.

-

Negative Pressure Fans: Maintain controlled environments to prevent hazardous gas leaks.

10. Logistics and Storage Ventilation

Proper air circulation in waste storage and processing areas prevents the buildup of gases and reduces material degradation.

-

Warehouse Ventilation Fans: Prevent heat accumulation in waste storage areas.

-

Container Ventilation Fans: Ensure proper airflow in sealed waste containers to prevent decomposition-related gas buildup.

-

Truck Loading Dock Exhaust Fans: Remove fumes from waste transport vehicles during loading and unloading.

Conclusion

Industrial fans are vital in the waste recycling industry, enhancing air quality, safety, and operational efficiency. Their role in ventilation, dust control, odor management, cooling, and material transport ensures that recycling facilities operate smoothly while maintaining environmental and workplace safety standards. By selecting the right type of fan for each recycling process, companies can optimize performance, reduce hazards, and contribute to a cleaner, more sustainable waste management system.