Project Information

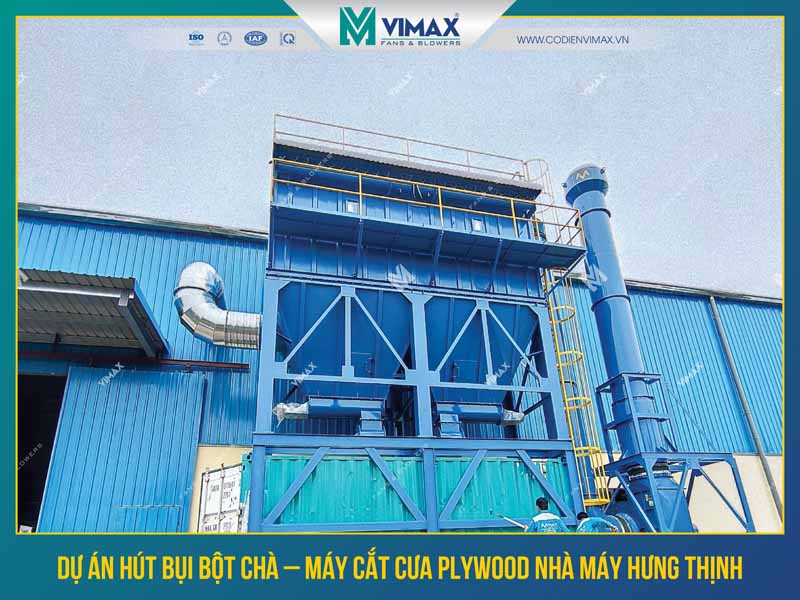

- Project: Dust extraction of sanding powder – Plywood saw cutting machine

- Factory: Hung Thinh Bac Giang Wood Factory

- Construction site: Lang Giang, Bac Giang

Project Specifications

- Capacity: 200KW

- Pressure: 3500pa

- Material: SS400 steel

- Flow rate: 180,000 m3/h

Advanced Features Of The System

- Wood dust is easily dispersed into the environment on a very large scale of dispersion, not only at the production site. Installing a cyclone technology wood dust treatment system and a fabric bag filter is the most superior solution applied by many manufacturing units

- Inverter control frequency converter maximizes the system’s efficiency, safety, and energy saving.

- There is a siren alarm system when electrical short circuits and motor overloads occur.

Purpose Of Use

Good quality must collect relatively clean (over 90%) wood powder dust during transportation, cutting, and carving. A stable operating system creates a healthy working environment.

For Investors

- Protect the environment according to current regulations

- Ensure processing flow

- Long operating time

- Easy to replace absorbent materials, cost savings

- The system is easy to operate and ensures odor treatment quality

- Increase the output product quality

For Workers

- Work in a clean environment

- Reduce the cause of diseases and protect the health of machine operators

- Increase work efficiency

Some Images Of The Project

Plywood Dust Extraction System At Hung Thinh Bac Giang Wood Factory

Plywood Dust Extraction System At Hung Thinh Bac Giang Wood Factory

Plywood Dust Extraction System At Hung Thinh Bac Giang Wood Factory

Plywood Dust Extraction System At Hung Thinh Bac Giang Wood Factory