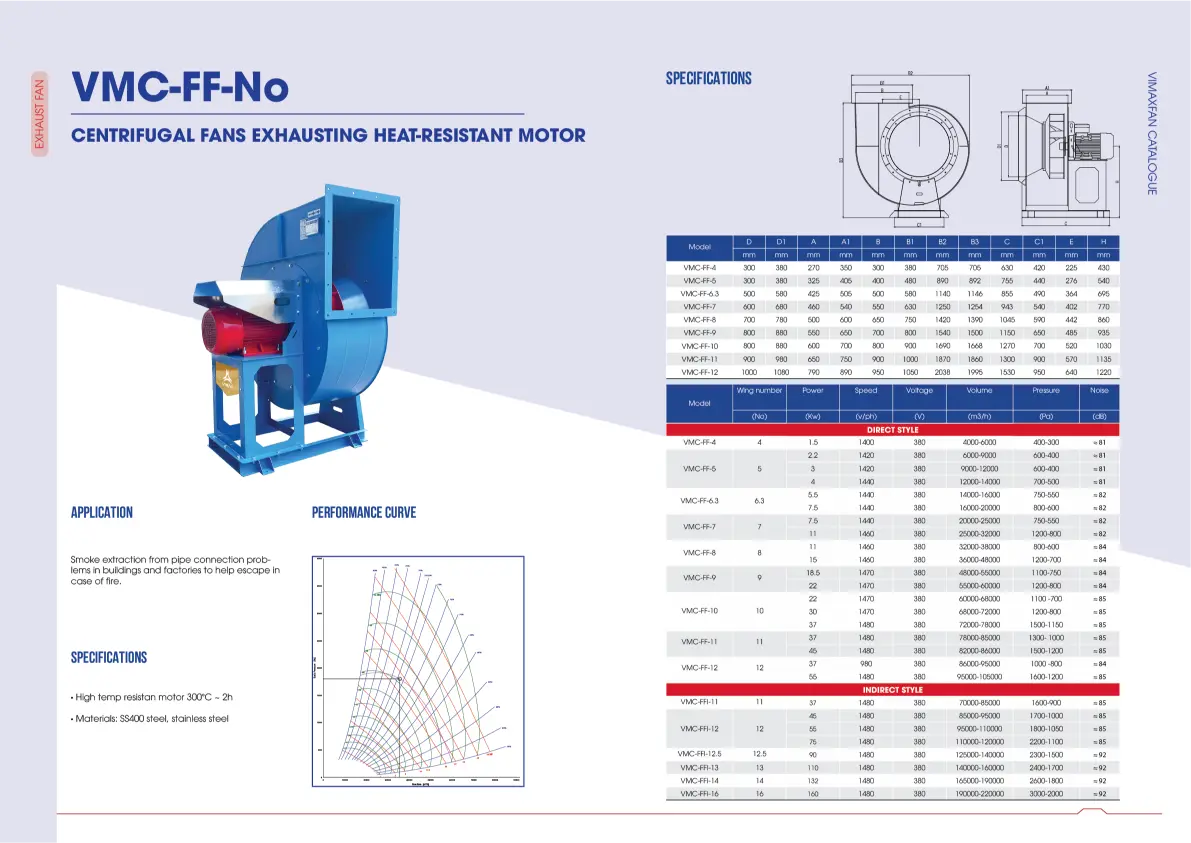

The VMC-FF-No centrifugal fan is designed for emergency smoke extraction, capable of continuous operation at extremely high temperatures—typically 250°C for 2 hours or up to 300°C briefly (depending on model). The fire-rated motor uses F or H-class insulation, with thermal protection and special bearings. Its backward-curved impeller generates high static pressure, suitable for long duct networks with multiple intake points. The casing is insulated with ceramic wool or fire-resistant materials, heat-resistant coated, and epoxy-finished to resist corrosion. The system can include thermal sensors, pressure switches, and centralized fire panel integration. Available in direct or belt-drive setups based on motor placement. Lab-tested and certified to European standard EN 12101-3. Ideal for underground garages, malls, office towers, factories, logistics warehouses, and production facilities.

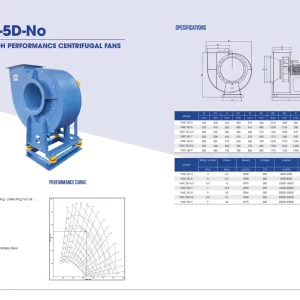

Technical Specifications:

- Airflow: 4,000 – 120,000 m³/h

- Pressure: 800 – 3500 Pa

- Fire resistance: 250°C for 2 hours

- Power: 2.2kW – 75kW

- Drive: Direct or belt

- Material: Heat-resistant steel casing, steel blades, H-class motor

- Standards: EN 12101-3, ISO 5801, TCVN 2622

- Noise: < 82 dB

Here is the professional English translation of your full paragraph, maintaining a technical and corporate tone:

The VMC-FF-No is manufactured at VIMAX GLOBAL’s ISO 9001:2015-certified facility. Constructed from CT3 or stainless steel, it features high-temperature coatings (300°C+) and ceramic wool fire insulation. Impellers are G2.5 dynamically balanced, and motors use high-temp grease-lubricated bearings. Every unit undergoes airflow, pressure, vibration, and fire simulation testing in a heat chamber.

Custom design is available based on dimensions, power, discharge direction, mounting configuration, and automation control integration. VIMAX supplies full CO, CQ, technical drawings, QR traceability, and certified testing documentation to meet consultant, fire protection, and project management standards.

All products undergo rigorous quality control testing to guarantee high performance, quiet operation, and minimal maintenance. VIMAX also offers strong customer support and expert technical consultation to meet the diverse needs of clients both domestically and internationally.

For more information about VIMAX or to request customized product designs, please contact us.

Shipping Information

Shipping policies vary depending on the manufacturer, as we work with multiple partners. Freight is typically included to a standard commercial or industrial address. However, deliveries to non-standard locations may incur additional costs.

Standard Delivery

A typical delivery location can accommodate a semi-trailer truck with a standard 53’ trailer and has the means to offload the equipment. Equipment is generally delivered to the tailgate of the truck. The carrier does not unload the equipment unless prior arrangements have been made. It is the receiver’s responsibility to remove the equipment from the truck. If alternative delivery arrangements are required, they can be coordinated at the time of order placement.

Delivery Options

- Liftgate Delivery: If you lack a dock or forklift to offload the equipment, it’s recommended to request liftgate delivery. This option ensures the carrier lowers the equipment to ground level.

- Delivery Appointments: Delivery appointments or notifications before delivery are available. These options must be requested at the time of order and may involve additional fees.

- Big City Delivery: Deliveries to downtown or congested urban areas may incur additional costs due to limited access.

- Remote Area Delivery: Deliveries to remote locations may incur additional charges to account for the added transit time.

- Residential Delivery: Deliveries to residential areas typically require a liftgate truck and may involve additional fees.

- Redelivery: If delivery is attempted but not completed, redelivery fees will apply. The carrier does not automatically reattempt delivery without authorization.

Damages and Shortages

- Visible External Damage: Document any visible damage on the freight bill or receipt and have it signed by the driver upon delivery.

- Concealed Internal Damage: Inspect the equipment immediately upon receipt. Report any concealed damage to the carrier within ten days.

- Shortages: Notify us within three days of receipt if there are any shortages.

- Important: Always inspect freight upon receipt. Document any visible damage, take photos, and notify the delivery driver. You may also refuse delivery if the equipment is visibly damaged, and it will be returned to the manufacturer.

Warranty & Return Policy

Terms of Sale

-

Payment Methods: Payment by Telegraphic Transfer (T/T) or Letter of Credit (L/C).

-

Price Policy: All prices are subject to change depending on market conditions and will be notified accordingly.

-

Sales Taxes: Unless otherwise specified, prices exclude taxes and fees. Any applicable local, state, or federal taxes will be added to the invoice and are the buyer’s responsibility.

Conditions of Sale

-

Claims: The seller’s responsibility ends once the goods are handed over to the carrier in good condition. The buyer is responsible for filing any claims related to damage, shortages, or losses during transit with the carrier. We will assist where possible. Claims for factory shortages must be submitted within 60 days of receipt.

-

Acceptance or Approval: Equipment purchased subject to third-party approval (e.g., by an architect or engineer) is not guaranteed to meet specifications written for other manufacturers.

-

Limitation of Liability: The seller’s liability is limited to repair, replacement, or refund at their discretion. No responsibility is accepted for misuse, improper storage, or operation. No liability is assumed for incidental or consequential damages.

-

Dispute Resolution: All disputes will be resolved through binding arbitration under the rules of the American Arbitration Association (AAA) in Skokie, Illinois, governed by Illinois state law.

-

Delays: The seller is not liable for delays caused by force majeure events such as natural disasters, strikes, accidents, material shortages, or circumstances beyond control.

-

Credit: If the buyer’s credit is deemed insufficient, the seller reserves the right to delay shipment or cancel the order.

-

Penalty Clauses: Any penalty clauses are only valid if expressly approved in writing by a company officer.

Order Cancellation

-

The buyer shall reimburse incurred expenses if the order is canceled without fault on the seller’s part.

-

A 50% fee applies to non-stock replacement parts.

-

A 30% fee (minimum $125) applies if the order is in production or completed.

-

A $150 fee applies if the order has been entered but production has not started.

-

No fee applies if the order has not been entered into the system.

Important Notes

-

VIMAX Industrial Fans are manufactured by a leading provider of industrial ventilation solutions.

-

VIMAX is committed to innovation – quality – performance, specializing in the design and manufacturing of efficient, durable, and flexible airflow systems across a wide range of industries.

-

Every product is built to strict industrial standards, using advanced manufacturing technology and premium materials such as carbon steel, stainless steel, and aluminum for long-lasting reliability.

-

All products undergo rigorous quality control to ensure efficient operation, low noise levels, and minimal maintenance requirements.

-

VIMAX offers comprehensive customer service and technical support to meet the diverse needs of clients both domestically and internationally.

All claims related to visible or concealed damage must be reported immediately to the carrier with photo documentation. Safe delivery is the carrier’s responsibility, and the buyer is responsible for filing any necessary claims.