As we move towards 2025, the need for cleaner air in industrial settings is more pressing than ever. Innovations in industrial air filtration systems are at the forefront of this change, aiming to improve air quality while promoting sustainability. In this article, we will explore the latest advancements in filtration technology, sustainability efforts, smart technology integration, regulatory compliance, customization options, collaboration with industry leaders, and future trends in air quality management.

Key Takeaways

- New filtration technologies like HEPA and nanofiber materials are improving air quality.

- Sustainability is becoming a priority with energy-efficient systems and recyclable materials.

- Smart technologies are enhancing monitoring and maintenance of filtration systems.

- Regulatory compliance is crucial as industries adapt to new air quality standards.

- Customization of filtration systems is key to meeting the unique needs of different industries.

Advancements In Filtration Technology

It’s a new era for industrial air filtration! We’re seeing some serious upgrades in the tech that keeps our air clean. These advancements aren’t just about meeting regulations; they’re about improving efficiency, reducing costs, and ensuring a healthier environment for everyone. VIMAX is committed to staying at the forefront, offering solutions that are both innovative and reliable.

High-Efficiency Particulate Air Filters

HEPA filters have been around for a while, but they’re getting a major boost. New designs and materials are pushing their efficiency even higher, capturing more of those ultra-fine particles that used to slip through. This means cleaner air and a safer workspace. Plus, longer filter life reduces downtime and replacement costs. Think of it as a smart investment in your facility’s future.

Electrostatic Precipitators

Electrostatic precipitators (ESPs) are getting smarter too. We’re seeing more advanced control systems that optimize performance based on real-time conditions. This leads to better energy efficiency and reduced maintenance. ESPs are great for handling large volumes of dust and particulate matter, making them ideal for industries like power generation and cement production. They’re a solid choice for industrial air filtrations.

Nanofiber Filter Media

Nanofiber technology is a game-changer. These filters use incredibly fine fibers to create a dense network that traps even the smallest particles. This results in superior filtration efficiency and lower pressure drop, which means less energy consumption. Nanofiber media is also more durable and resistant to moisture and chemicals, extending its lifespan. It’s a premium option for businesses that demand the best. VIMAX is actively exploring nanofiber applications to enhance our product line.

Choosing the right filtration technology depends on your specific needs and industry. Consider factors like particle size, air volume, and operating conditions. A thorough assessment will help you select the most effective and cost-efficient solution.

Here’s a quick guide to help you decide:

- HEPA Filters: Best for applications requiring very high filtration efficiency, such as cleanrooms and pharmaceutical manufacturing.

- Electrostatic Precipitators: Ideal for large-scale operations with high dust loads, like power plants and foundries.

- Nanofiber Filters: A premium choice for superior performance and energy efficiency in demanding environments.

Ready to upgrade your industrial air filtration system? Contact us today to discuss your specific requirements and explore the best solutions for your business. We’re here to help you achieve cleaner air and a healthier bottom line.

Sustainability In Industrial Air Filtration

Sustainability is no longer a ‘nice-to-have’ but a core business imperative. For industrial air filtration, this means a shift towards solutions that minimize environmental impact while maximizing operational efficiency. We’re seeing increased demand for systems that not only clean the air but also contribute to a company’s overall sustainability goals. VIMAX is committed to providing solutions that meet these evolving needs.

Energy-Efficient Systems

Let’s be real, older filtration systems can be energy hogs. The future is about minimizing energy consumption without sacrificing performance. This involves optimizing fan design, reducing pressure drops across filters, and integrating smart controls to adjust airflow based on real-time conditions.

Here’s what to look for when evaluating energy-efficient systems:

- Variable Frequency Drives (VFDs): Allow fans to operate at optimal speeds, reducing energy waste.

- High-Efficiency Motors: Using IE3 or IE4 motors can significantly lower energy consumption.

- Smart Controls: Systems that automatically adjust airflow based on demand.

Recyclable Filter Materials

The dirty secret of filtration is what happens to the filters after they’re used. Landfilling tons of spent filter media isn’t sustainable. The industry is moving towards recyclable and biodegradable filter materials. This includes exploring options like:

- Cellulose-based filters with biodegradable coatings.

- Metal filters designed for easy cleaning and reuse.

- Partnerships with recycling companies to reclaim valuable materials from spent filters.

Carbon Footprint Reduction Strategies

Beyond energy efficiency and recyclable materials, a holistic approach to carbon footprint reduction is essential. This involves evaluating the entire lifecycle of the filtration system, from manufacturing to disposal. VIMAX is actively working to minimize its carbon footprint through:

- Optimizing manufacturing processes to reduce waste and energy consumption.

- Sourcing materials from suppliers with strong sustainability practices.

- Designing systems for longer lifespans and reduced maintenance requirements.

Implementing carbon footprint reduction strategies isn’t just about being environmentally responsible; it’s also about improving your bottom line. Reduced energy consumption, waste disposal costs, and material usage all translate to significant cost savings.

Ready to explore sustainable air filtration systems that align with your business goals? Contact us today to discuss your specific needs and how VIMAX can help you achieve a cleaner, greener future.

Integration Of Smart Technologies

Smart tech is changing how we handle industrial air filtration. It’s not just about cleaner air anymore; it’s about smarter, more efficient systems that save you money and reduce downtime. VIMAX is committed to providing solutions that are not only effective but also future-proof, ensuring your operations are ready for whatever comes next.

IoT-Enabled Monitoring Systems

Imagine knowing exactly how your air filtration system is performing, all the time, from anywhere. That’s the power of IoT. These systems use sensors to track key metrics like filter pressure, airflow, and contaminant levels. This data is then sent to a central dashboard, giving you a real-time view of your system’s health. This is especially useful for companies looking to expand their operations internationally, as it allows for remote monitoring and management of air filtration systems across multiple locations.

Here’s what you can expect:

- Real-time data: Access up-to-the-minute performance metrics.

- Remote monitoring: Keep an eye on your systems from anywhere in the world.

- Customizable alerts: Get notified when something needs attention.

Predictive Maintenance Solutions

No one likes unexpected downtime. Predictive maintenance uses the data from IoT sensors to forecast when maintenance will be needed. Instead of relying on fixed schedules, you can perform maintenance only when it’s actually necessary. This saves time, reduces costs, and extends the life of your equipment. VIMAX is dedicated to helping you minimize disruptions and maximize the return on your investment.

Benefits of predictive maintenance:

- Reduced downtime

- Lower maintenance costs

- Extended equipment life

Data Analytics for Performance Optimization

Data is only useful if you can make sense of it. Data analytics tools take the information gathered by IoT sensors and turn it into actionable insights. You can identify trends, optimize filter change schedules, and fine-tune your system for maximum efficiency. This leads to better air quality, lower energy consumption, and a healthier bottom line. VIMAX provides the tools and support you need to make the most of your data.

By using data analytics, you can continuously improve your air filtration system’s performance. This not only ensures compliance with regulations but also helps you achieve your sustainability goals.

Ready to take your industrial air filtration to the next level? Contact us today to learn more about how VIMAX can help you integrate smart technologies into your operations.

Regulatory Compliance And Standards

Navigating the world of industrial air filtration means understanding a whole bunch of rules and regulations. It’s not just about making sure your air is clean; it’s about proving it and staying compliant. For B2B buyers, this is super important because it affects everything from product quality to export readiness. VIMAX understands these challenges and is committed to helping you meet and exceed these standards.

Understanding EPA Regulations

The Environmental Protection Agency (EPA) sets the baseline for air quality standards in the US. It’s a big deal. They have rules about what pollutants are allowed and how much of them. Staying on top of these regulations is key to avoiding fines and keeping your operations running smoothly.

- The EPA has different rules for different industries, so you need to know what applies to you.

- They also update these rules regularly, so you can’t just set it and forget it.

- VIMAX can help you understand which EPA regulations affect your business.

ISO Standards for Air Quality

ISO standards are international. They show that you’re serious about quality and environmental responsibility. ISO standards for air quality, like ISO 16890, give you a framework for testing and classifying air filters. This helps you compare different filters and choose the right one for your needs.

- ISO 16890 is the global standard for testing air filters.

- It classifies filters based on their ability to capture different sizes of particles.

- Meeting ISO standards can open doors to international markets.

Industry-Specific Compliance Requirements

Different industries have different needs, and that means different rules. Food processing plants have different air quality concerns than, say, a metalworking shop. You need to know the specific rules for your industry to stay compliant. Here’s a quick guide:

- Pharmaceuticals: Strict requirements for cleanrooms and sterile environments.

- Food Processing: Regulations to prevent contamination and ensure food safety.

- Manufacturing: Rules to protect workers from dust, fumes, and other pollutants.

Keeping up with all these regulations can be a headache. That’s why VIMAX offers solutions designed to meet the specific needs of your industry. We can help you choose the right filters, design a compliant system, and stay ahead of the curve.

Ready to ensure your industrial air filtration systems meet all necessary regulations and standards? Contact us today to discuss your specific needs and how VIMAX can help you achieve compliance and maintain export readiness.

Customization And Modular Solutions

In the evolving landscape of industrial air filtration, one size rarely fits all. That’s why customization and modularity are becoming increasingly important. We understand that your specific operational needs, facility layout, and regulatory requirements demand solutions tailored to your unique challenges. VIMAX is committed to providing flexible, scalable systems that adapt to your business, not the other way around.

Tailored Filtration Systems

Forget off-the-shelf solutions that compromise on performance. We work closely with you to design air filtration systems that address your specific pollutants, airflow demands, and space constraints. Our engineering team conducts thorough site assessments and collaborates with your team to develop a system that optimizes efficiency and minimizes downtime. This collaborative approach ensures that the final product aligns perfectly with your operational goals and environmental responsibilities.

Here’s what you can expect from our tailored solutions:

- Detailed consultation to understand your needs.

- Custom design and engineering.

- Performance modeling and simulations.

- Ongoing support and optimization.

Scalable Modular Designs

Modularity offers unparalleled flexibility. Our systems are designed with interchangeable components, allowing you to easily expand or reconfigure your filtration setup as your business grows or your needs change. This approach not only protects your initial investment but also ensures that your system remains effective and compliant over the long term. With modular designs, you can add capacity, upgrade components, or relocate sections of your system with minimal disruption to your operations.

Benefits of modularity include:

- Easy expansion and reconfiguration.

- Reduced downtime during upgrades.

- Simplified maintenance and repairs.

- Cost-effective scalability.

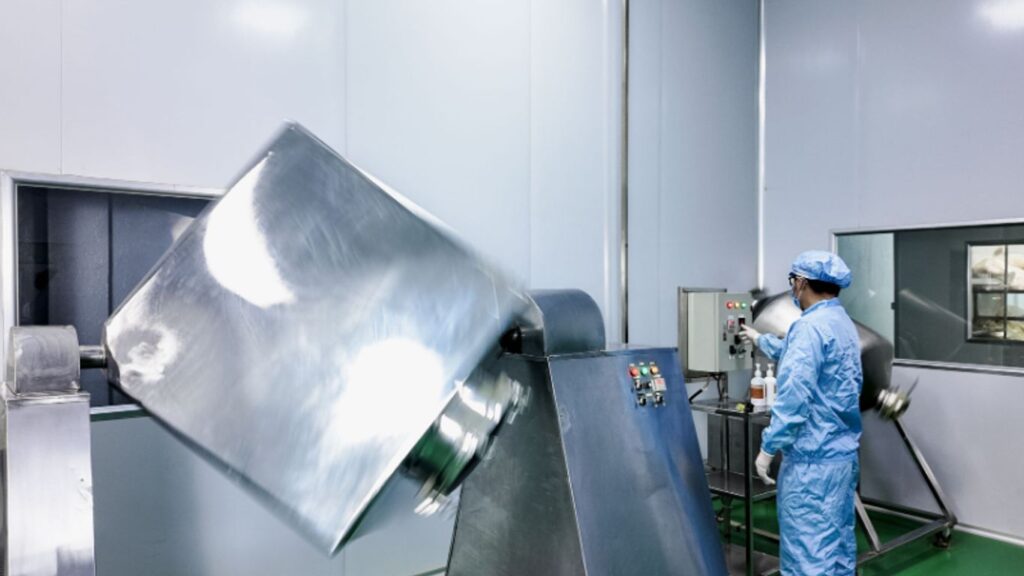

Client-Specific Applications

We recognize that different industries have different needs. A food processing plant, for example, has very different air quality concerns than a metal fabrication facility. That’s why we specialize in developing client-specific applications that address the unique challenges of your industry. Whether you need to control dust, fumes, odors, or other airborne contaminants, we have the expertise and experience to deliver a solution that meets your exact requirements. VIMAX is dedicated to providing high-quality, export-ready solutions that you can trust.

Investing in a customized, modular air filtration system is an investment in the future of your business. It demonstrates a commitment to environmental responsibility, employee health, and operational efficiency. By choosing a solution tailored to your specific needs, you can minimize costs, maximize performance, and ensure long-term compliance.

Ready to discuss your specific air filtration needs? Contact us today to schedule a consultation and discover how our customized, modular solutions can help you achieve your clean air goals.

Collaboration With Industry Leaders

In the rapidly evolving landscape of industrial air filtration, staying ahead requires more than just internal innovation. Strategic alliances and collaborative efforts are now essential for driving progress and meeting increasingly stringent demands. We at VIMAX recognize this and actively seek partnerships that enhance our capabilities and broaden our reach.

Partnerships With Technology Providers

We believe that partnering with leading technology providers is key to integrating cutting-edge solutions into our air filtration systems. These collaborations allow us to access the latest advancements in materials, sensors, and control systems, ensuring that our clients benefit from the most effective and efficient technologies available. By working closely with these specialists, we can customize solutions to meet specific industry needs and regulatory requirements.

Here’s what we look for in a technology partner:

- Proven track record of innovation

- Commitment to quality and reliability

- Ability to provide customized solutions

- Strong technical support and training

Joint Ventures For Innovation

Joint ventures represent a deeper level of collaboration, allowing us to combine our expertise with that of other industry leaders to develop entirely new air filtration solutions. These ventures enable us to share resources, mitigate risks, and accelerate the pace of innovation. For example, we are currently involved in a joint venture focused on developing next-generation nanofiber filter media, which promises to significantly improve filtration efficiency and reduce energy consumption. Consider cooling ventilations for your next project.

Collaborative Research Initiatives

We are committed to supporting collaborative research initiatives that advance the science of air filtration. By working with universities, research institutions, and industry consortia, we can contribute to the development of new knowledge and technologies that benefit the entire industry. These initiatives also provide valuable opportunities for our engineers and scientists to stay at the forefront of their fields.

Participating in research projects allows us to validate our technologies, refine our designs, and ensure that our products meet the highest standards of performance and reliability. It’s about building trust through verifiable results.

We invite you to explore partnership opportunities with VIMAX. Contact us today to discuss how we can collaborate to create a cleaner, healthier future.

Future Trends In Air Quality Management

Emerging Technologies

The future of industrial air filtration is looking pretty interesting, with a bunch of new tech on the horizon. We’re talking about things like self-cleaning filters, advanced sensor tech, and even the use of AI to optimize filtration processes. These technologies promise better efficiency, lower maintenance costs, and a smaller environmental footprint. For example, VIMAX is exploring the use of photocatalytic oxidation (PCO) in some of its air filtration systems, which could be a game-changer for removing volatile organic compounds (VOCs).

Here’s a quick look at some of the emerging technologies:

- Self-Cleaning Filters: Reduces maintenance and downtime.

- AI-Powered Optimization: Adjusts filtration based on real-time data.

- Advanced Sensor Technology: Provides detailed air quality monitoring.

Market Demand Shifts

What people want is changing, and that’s affecting the air filtration market too. There’s a growing demand for systems that are not only effective but also sustainable and energy-efficient. Companies are under pressure to reduce their carbon footprint and comply with stricter environmental regulations. This means a bigger focus on things like recyclable filter materials and energy-saving designs. The global industrial air filtration market is expected to expand, so it’s important to stay ahead of the curve.

Consider these factors driving market shifts:

- Increased focus on sustainability.

- Stricter environmental regulations.

- Growing demand for energy-efficient systems.

Impact of Climate Change on Filtration Needs

Climate change is making air quality worse, no doubt about it. More extreme weather events, like wildfires and dust storms, are pumping more pollutants into the air. This means industrial facilities need more robust and adaptable cooling ventilations to deal with these challenges. We’re talking about systems that can handle higher concentrations of particulate matter and a wider range of pollutants. It’s not just about meeting current standards; it’s about preparing for a future where air quality is even more unpredictable.

Investing in advanced air filtration now is an investment in the future. As climate change continues to impact air quality, the demand for effective and adaptable filtration solutions will only increase. Companies that prioritize air quality management will be better positioned to thrive in a changing world.

Interested in learning more about how VIMAX can help you prepare for the future of air quality management? Contact us today to discuss your specific needs and explore our range of dust collectors and solutions.

As we look ahead, air quality management is changing fast. New technologies and ideas are helping us keep our air cleaner and healthier. It’s important for everyone to stay informed about these changes. Visit our website to learn more about how you can help improve air quality in your community!

Looking Ahead: The Path to Cleaner Air

As we move toward 2025, the advancements in industrial air filtration systems are set to play a key role in improving air quality across various sectors. Companies like VIMAX are at the forefront of this change, offering innovative solutions that not only meet regulatory standards but also enhance operational efficiency. By investing in these technologies, businesses can significantly reduce their environmental impact while ensuring a healthier workplace for their employees. It’s clear that the future of clean air is not just a goal but a necessity, and with the right partnerships and technologies, we can achieve it together.

Frequently Asked Questions

What are the latest improvements in air filters?

New air filters are now more efficient. They can catch tiny particles that can harm health, making the air cleaner.

How do energy-efficient systems work?

Energy-efficient systems use less power while still cleaning the air well. This helps save money and is better for the planet.

What materials are used in modern air filters?

Many new filters use special materials that can be recycled. This means less waste and a healthier environment.

How can smart technology help with air filtration?

Smart technology can monitor air quality and tell you when to change filters. This keeps the air clean and saves time.

What rules do companies need to follow for air quality?

Companies must follow specific rules set by the EPA and other organizations to ensure the air is safe to breathe.

Why is VIMAX a good choice for air filtration systems?

VIMAX is known for making high-quality, customizable air filtration systems. They have a strong reputation and can meet different needs.